Side Draft

Paint booth devices typically refer to any type of structure that is designed to prevent contamination and unwanted airflow in areas involving painting. Over the years these technologies and industries have greatly improved. These products come in a variety of configurations ranging as small as a benchtop paint booth or as big as an aircraft paint booth.

Since the term paint booth can be somewhat a broad term there are a number of factors to consider when selecting the best paint booth for your application.

Paint booths offer a number of distinct advantages when used correctly. Cross-draft paint booths are very economical because they require the least amount of materials.

This type of paint booth does not require an upper plenum which is necessary for various other types of paint booths. Side draft paint booths are ideal for creating an even pattern of airflow around the painting area. This style of paint booth pulls the unwanted contaminates down and away from the finish. The disadvantage of this paint booth is it can be rather expensive as it requires ductwork and a number of exhaust fans. The user is also limited in the number of places he or she can stand so the overspray is caught in the airflow.

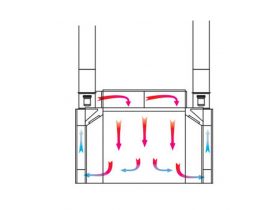

Downdraft paint booths offer a significant amount of cleanliness. Airflow is pulled around the painted object and then pushed away from underneath the object.

This allows for the user to stand at any location in the paint booth and the over-spray will be caught in the airflow. The risk of dust landing on the finish is greatly reduced with the downdraft paint booth design. This style of paint booth has additional start-up costs such as pits, tunnels, or ramps. Although this paint booth can be very expensive there is a trade-off of the number of corrections that are required after the paint has dried.

Side downdraft paint booths are an economical solution for shops that aren’t able to install a pit. Air comes into the booth through a full-length, filtered ceiling plenum, and flows downward over the product. When air reaches the floor, it is pulled into floor-level filtered exhaust plenums on both sides of the booth.