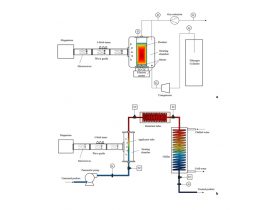

Microwave Heating System

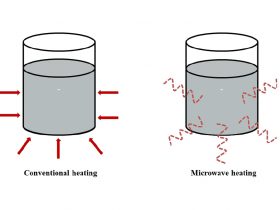

Microwave heating is a multiphysics phenomenon that involves electromagnetic waves and heat transfer; any material that is exposed to electromagnetic radiation will be heated up. The rapidly varying electric and magnetic fields lead to four sources of heating. Any electric field applied to a conductive material will cause current to flow. In addition, a time-varying electric field will cause dipolar molecules, such as water, to oscillate back and forth. A time-varying magnetic field applied to a conductive material will also induce current flow. There can also be hysteresis losses in certain types of magnetic materials.

Thermocoat provides various advanced and ingenious technical solutions to industry. We provide contemporary solutions which are easily adaptable and practical. Innovation in the field of heating systems is our focus and we strive to do so. On the basis of client requirements and application for which he is using the system. We have a dedicated team for continuous R&D and process improvement which allows us to get the possible and substantial results.

Benefits of Microwave Heating Systems

- Enhanced production quality

- Higher productivity

- Controlled environment

- Energy efficient

- Cost-effective

- Fast and uniform heating

- No pollution

- Selective processing

- User-friendly system

- Space convenient

- Guaranteed results

Applications

- Food Industry: Curing, Dairies, Confectionery, Fruits & Vegetable Canning, Dehydration, Pasteurizers, Vegetable Oil Refineries, etc.

- Chemical & Pharmaceutical Industries: Dyes and Intermediates, Refineries, Lube oil plants, Oil Reclamation, Additives, Adhesives, Pesticides, Fertilizers, etc.

- Rubber, Tyre Retreading, Paper & Board, Leather Industries, Plastic Industries.

- Cement Concrete/Mosaic Tiles Curing.

- Metal Pre-treatment, Timber Seasoning.